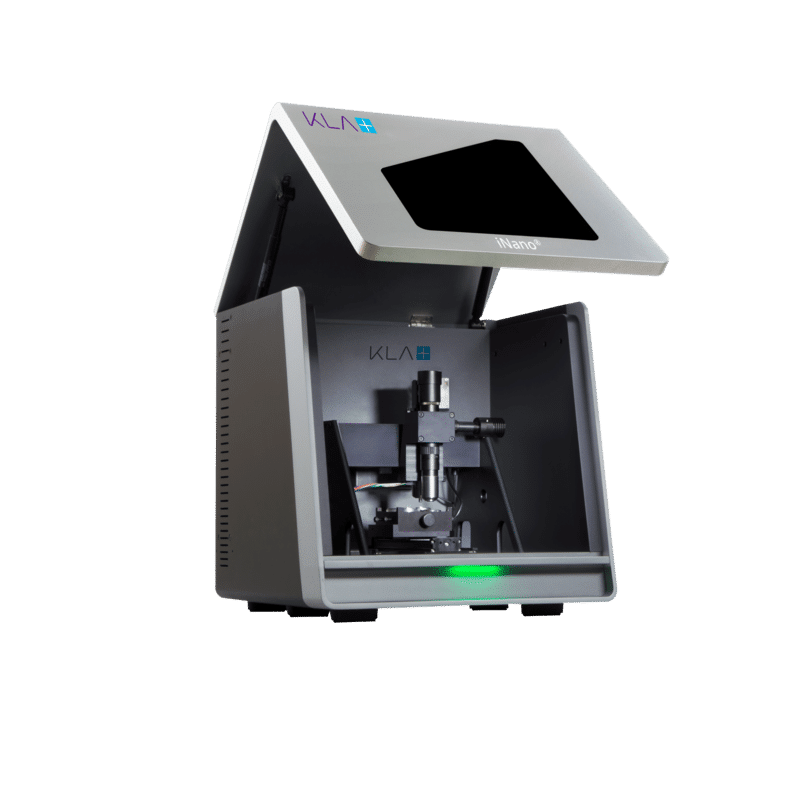

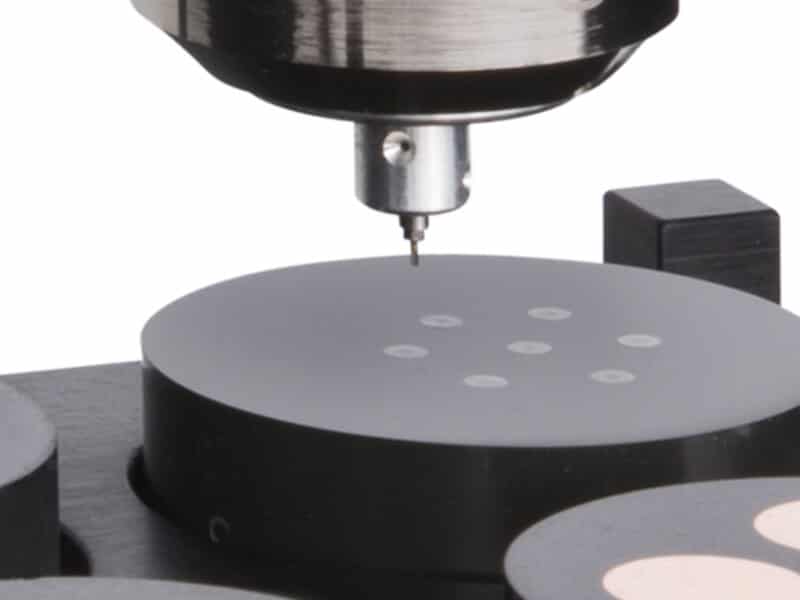

Nanoindenter up to 50 mN of force

iNano

2. Wide range of nanomechanical tests

3. Thin films and soft materials

(> 50 mN of force)

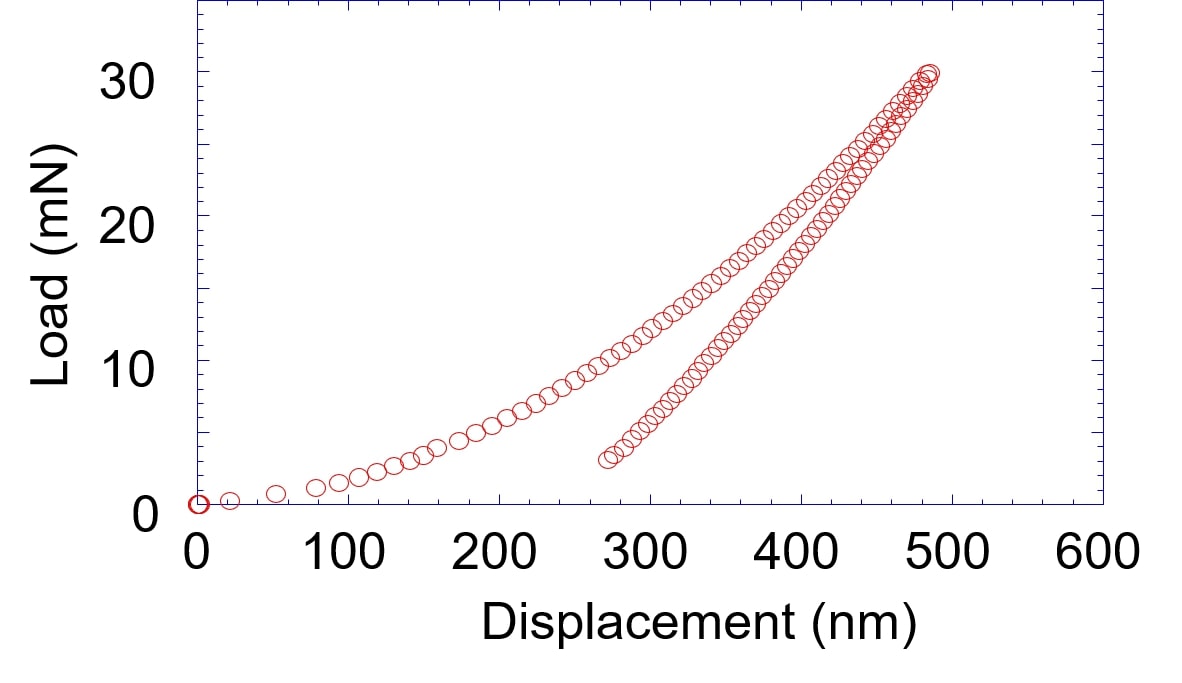

The INano Nanoindenter is a precise, flexible and user-friendly instrument allowing a wide range of nanomechanical tests, including the module and the hardness (Oliver and Pharr, ISO 14577), the storage and loss module and the universal tests. The iNano can exert up to 50 mN of force to test thin films and soft materials. Easy to use, the iNano offers a turnkey solution offering precision and precision, allowing superior nanomechanical tests to be performed in all laboratories, from the largest universities to high-tech companies.

Applications of nanoindentation

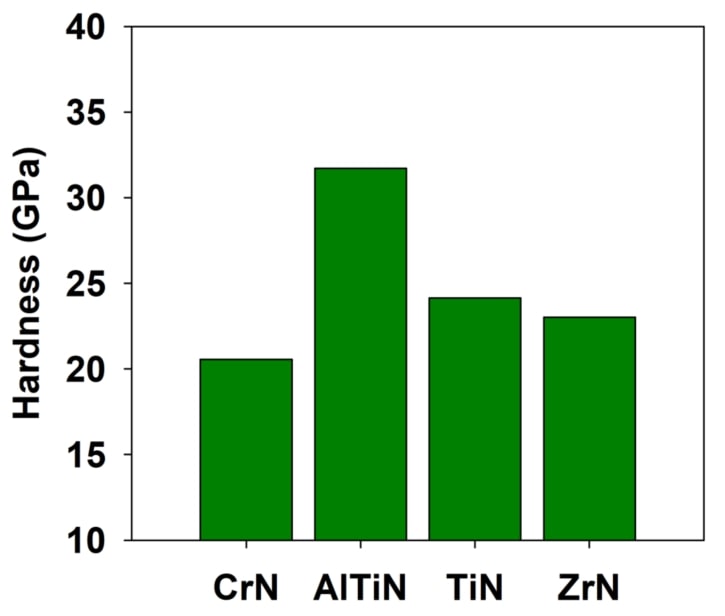

- Hardness and modulus measurements (Oliver-Pharr)

- High-speed hardware property cards

- ISO 14577 hardness test

- Delta polymer, storage and loss module

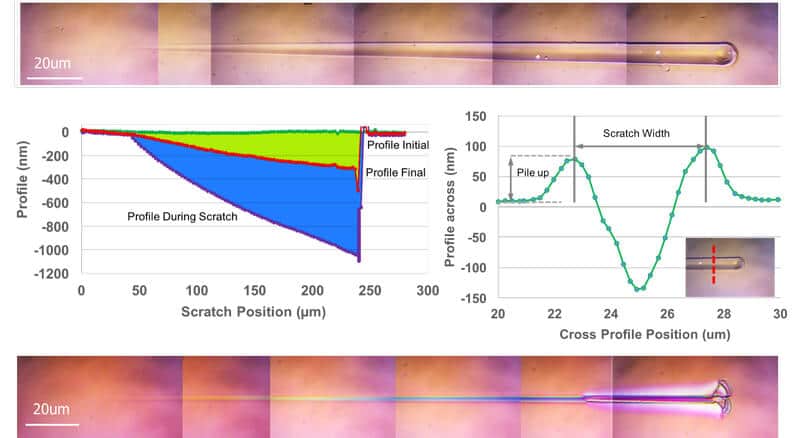

- Quantitative scratch and wear tests

- High temperature nanoindentation test

- Industries

- Hard coatings

- Semiconductor wafers

- Ceramics and Glasses

- metals and alloys

- Batteries and energy storage

- Research and development

- Pharmaceutical, food and personal care

- Automotive and aerospace

- Universal nanoscale trials

- Hard coatings

More info on applications

- Adhesion

- Hardness

- Young module

- Scratch

Nanoindentation with force up to 0.5mN

The iNano is equipped with the InForce 50 actuator for carrying out universal nanoindentation and nanomechanical tests. The 50 µN force and 50 µm displacement range of the InForce 50 allows the system to perform a wide range of tests. The InView software is a flexible and modern software package that facilitates nanoscale testing. The iNano is a compact platform with a high-speed InQuest controller and a vibration isolation gantry built into the housing. A wide range of materials and devices can be tested, including metals, ceramics, composites, thin films, coatings, polymers, biomaterials and gels.

ADVANTAGES

- Accurate, flexible and user-friendly

- Wide range of nanomechanical tests

- Thin layers and soft materials (> 50 mN of force)

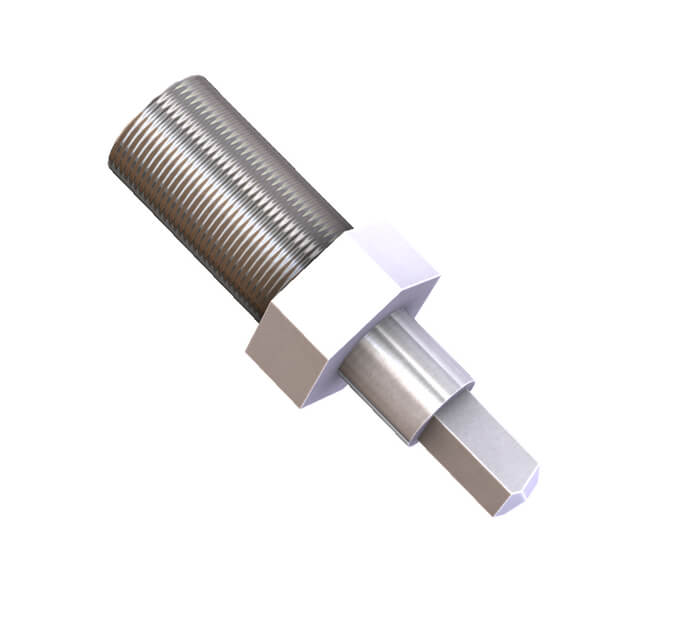

- InForce 50 actuator for capacitive displacement measurement and electromagnetic force actuation with interchangeable tips

- Unique tip calibration system built into the software for fast and accurate tip calibration

- InQuest high speed controller electronics with 100 kHz data acquisition rate and 20 µs time constant

- XY motion system with easy-mount magnetic sample holder

- Integrated microscope with digital zoom for precise targeting of the indentation

- ISO 14577 and standard test methods

- InView software package with RunTest, ReviewData, InFocus reports, InView University online training and InView mobile app

Options

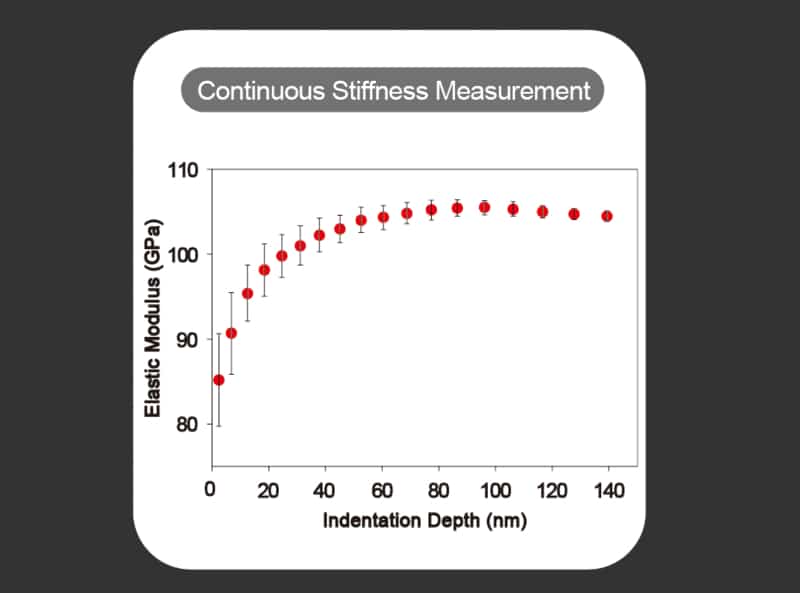

Continuous stiffness measurement (CSM)

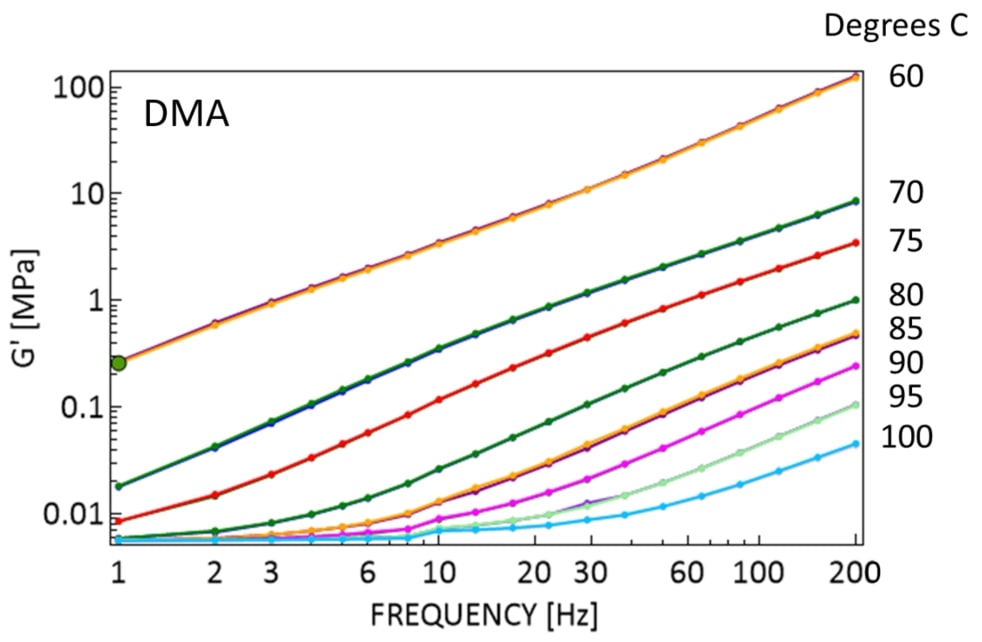

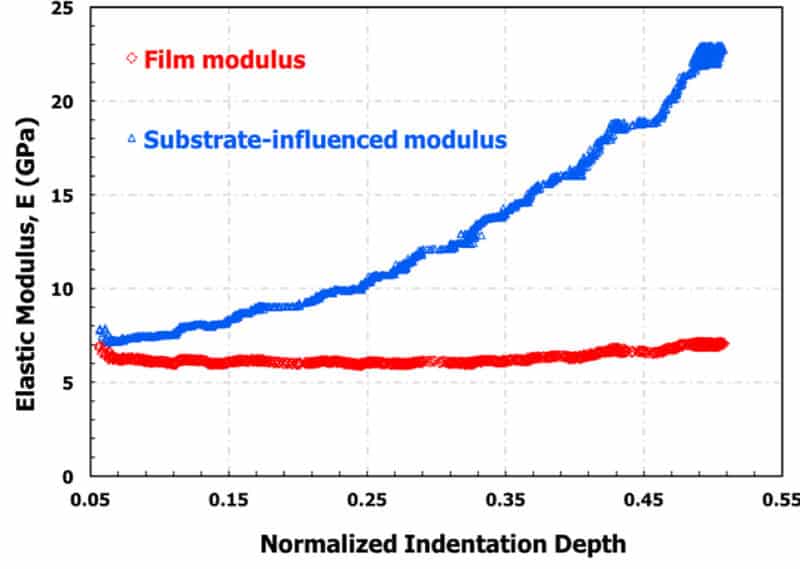

Continuous stiffness measurement is used to quantify the dynamic properties of the material, such as the rate of deformation and the effects induced by frequency. The CSM technique involves oscillation of the probe during indentation to measure properties as a function of depth, force, time or frequency. The option comes with a constant stress rate experience that measures hardness and modulus as a function of depth or load, the most common test method used in universities and industry. CSM is also used for other advanced measurement options, including the ProbeDMA ™ method for storage and loss module measurements and AccuFilm ™ measurements independent of the substrate. The CSM is integrated with the InQuest controller and InView software to provide ease of use and data quality.

The sample heating option at 300 ° C allows the sample to be placed in a chamber for uniform heating while undergoing simultaneous testing with the InForce 1000 or InForce 50 actuators. The option includes a high temperature control precision, filling with inert gas to reduce oxidation and cooling to eliminate waste heat. ProbeDMA, AccuFilm, NanoBlitz and CSM are all compatible with the sample heating option.

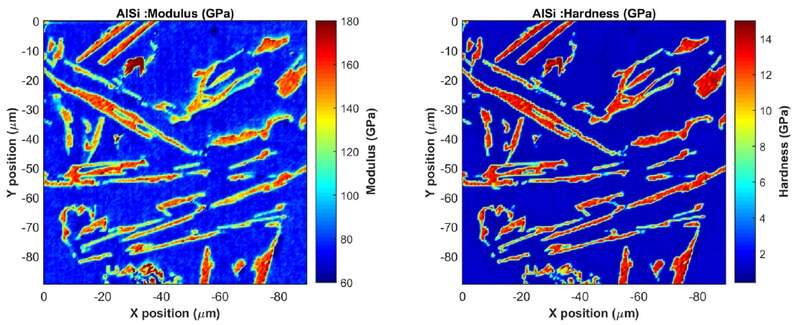

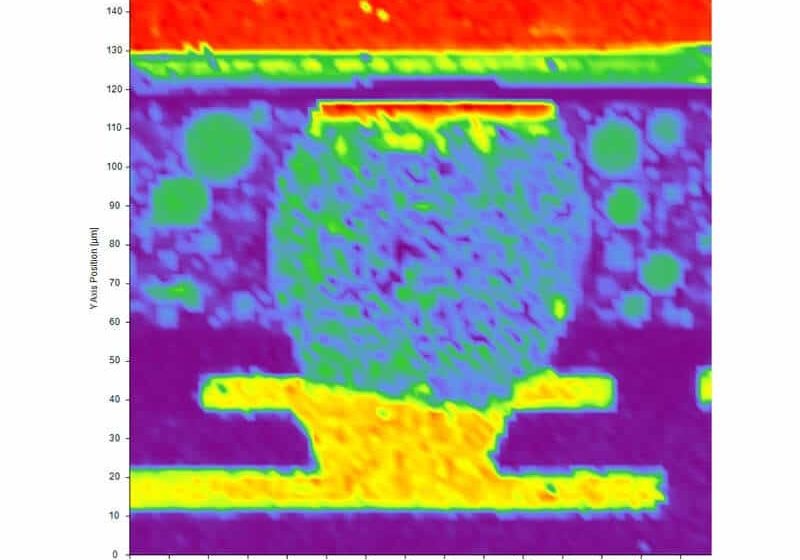

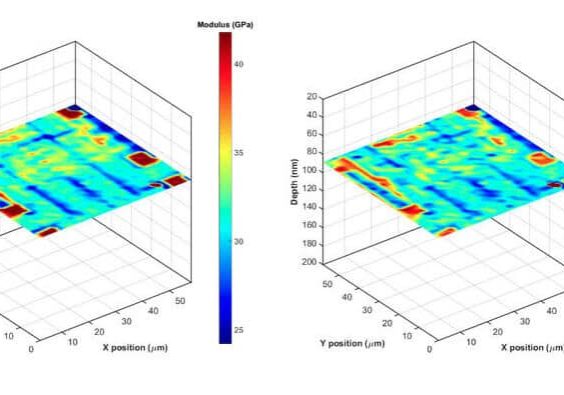

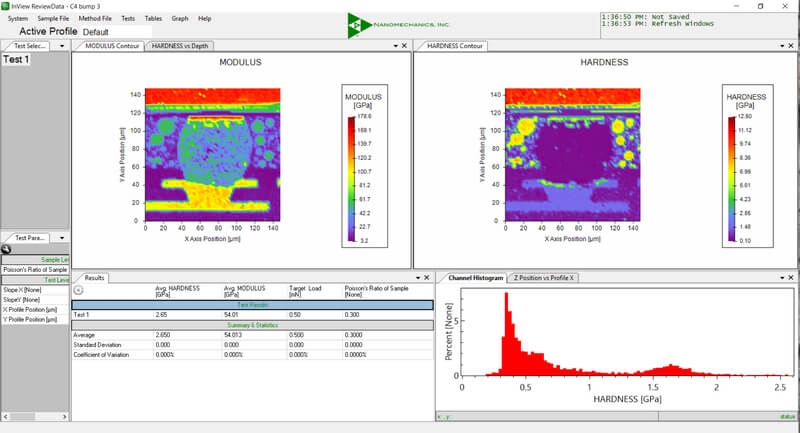

NanoBlitz 3D

NanoBlitz 3D uses the InForce 50 or InForce 1000 actuator and a Berkovich tip to generate 3D maps of nanomechanical properties for high E factor materials (> 3GPa). NanoBlitz performs up to 100,000 withdrawals (300x300 matrix) at <1 second per withdrawal and provides Young's modulus (E), hardness (H) and stiffness (S) values at a specified load for each withdrawal from the network . The large number of tests allows increased statistical precision. The histogram graphs show several phases or materials. The NanoBlitz 3D package includes visualization and data processing functionalities.

NanoBlitz 4D

NanoBlitz 4D uses the InForce 50 or InForce 1000 actuator and a Berkovich tip to generate 4D maps of the nanomechanical properties of low W / O and high E materials (> 3GPa). NanoBlitz performs up to 10,000 withdrawals (30x30 matrix) every 5 to 10 seconds and provides Young's modulus (E), hardness (H) and stiffness (S) values as a function of the depth of each withdrawal in the matrix. NanoBlitz 4D uses a constant strain rate method. The package includes visualization and data processing functionalities.

AccuFilm is an InView test method based on the Hay-Crawford model to measure the properties of materials independent of the substrate using continuous stiffness measurement (CSM). AccuFilm corrects the influence of the substrate on the film measurements for hard films on soft substrates, as well as for soft films on hard substrates.

Biomaterials Method Pack

The Biomaterials Method Pack offers the possibility of measuring the complex module of biomaterials with shear modules of the order of 1 kPa, and uses continuous stiffness measurement (CSM). The pack includes a flat tip and a test method to assess the viscoelastic properties. This measurement technique is essential for characterizing small-scale biomaterials that are not well served by traditional rheometric instruments.

The Biomaterials Method Pack offers the possibility of measuring the complex module of biomaterials with shear modules of the order of 1 kPa, and uses continuous stiffness measurement (CSM). The pack includes a flat tip and a test method to assess the viscoelastic properties. This measurement technique is essential for characterizing small-scale biomaterials that are not well served by traditional rheometric instruments.

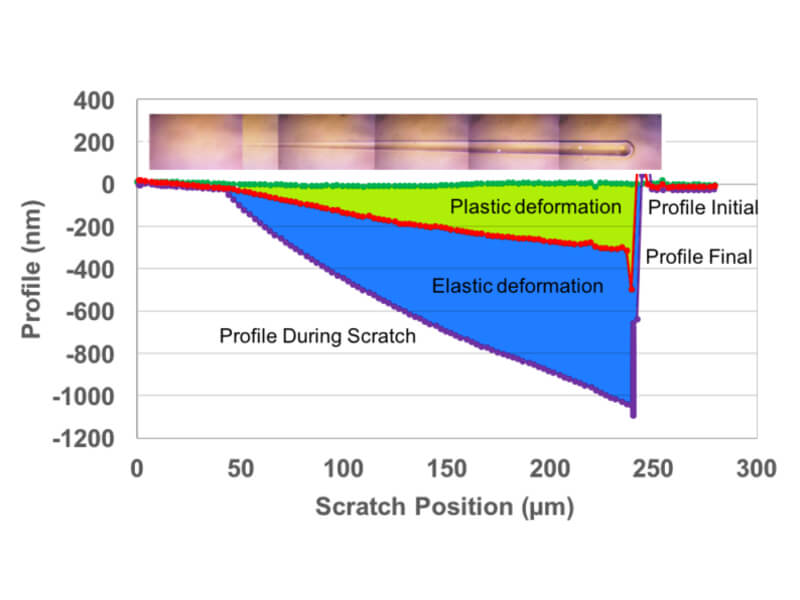

Scratch and wear test method

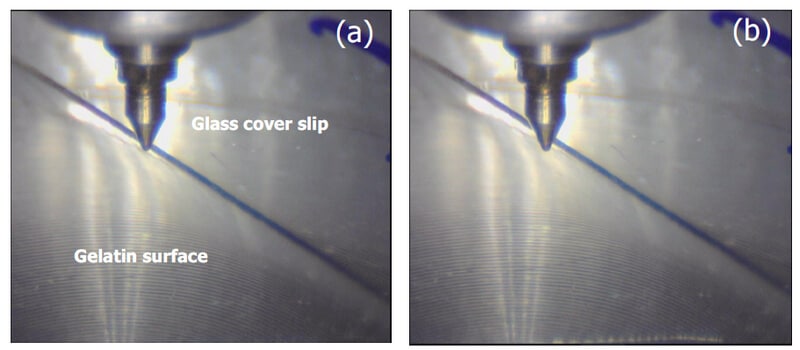

The scratch test involves applying a constant or ramped load to an indenter while crossing the surface of the sample at a specified speed. Scratch tests make it possible to characterize many materials such as thin films, fragile ceramics and polymers.

DataBurst

DataBurst allows systems with InView software and the InQuest controller to record displacement data at speeds> 1 kHz for the measurement of strain loads, jumps and other high-speed events. IMicro systems with the user method development option can also modify the methods for working with DataBurst.

Development of user methods for InView control software

InView is a powerful and intuitive platform for experiential scripting that can be used to design new or complex experiments. Experienced users can configure and perform virtually any small-scale mechanical test using the iMicro system equipped with the exclusive InView option.

True Test I-V Electrical measurements

Controlled via InView software, the True Test I-V option for the iMicro nanoindentor uses a precision ammeter and a voltage source, an electrical path crossing the tip and a conductive tip. This design allows the user to apply specific voltages to a sample and measure the tip current while simultaneously actuating the InForce 50 or InForce 1000 actuator.

Remote video option

The remote video option provides two additional viewing angles in the iNano chamber, in addition to the existing microscope objective. A holder is mounted to focus on the tip of the indenter during the test, an ideal configuration for bending and soft materials. The second support is mounted on the gantry to visualize both the sample and the microscope objective during the configuration of the test. The switching of the view between the standard microscope objective and the USB camera is software controlled.

Indentation tips and calibration samples

The InForce 50, InForce 1000 and Gemini actuators use interchangeable tips. A wide variety of vivid penetrations are available, such as Berkovich, cube corner and Vickers, as well as flat punches, sphere punches and other geometries. Standard reference materials and calibration standards are also available for the entire product range.

Contact us for more information on this product

Would you like an estimation ?

Additional information?

We will reply to you within 24 hours